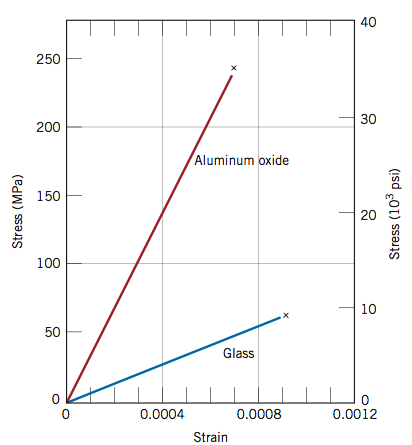

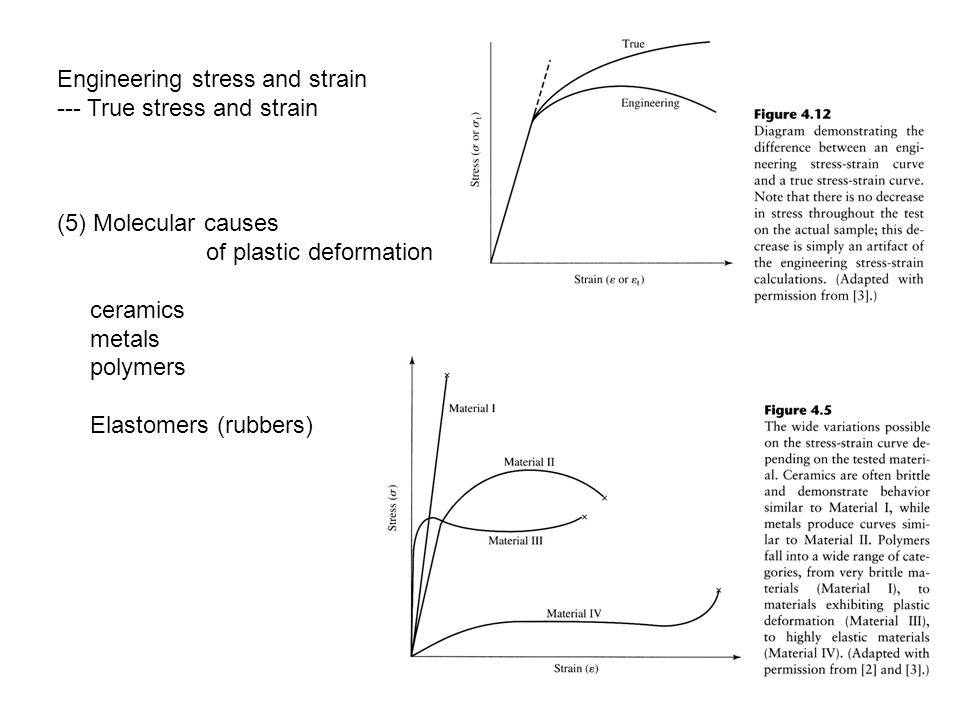

The hard fired materials exhibit straight line deformation to failure while the softer fired have a proportional elastic limit beyond which the stress strain curve deviates.

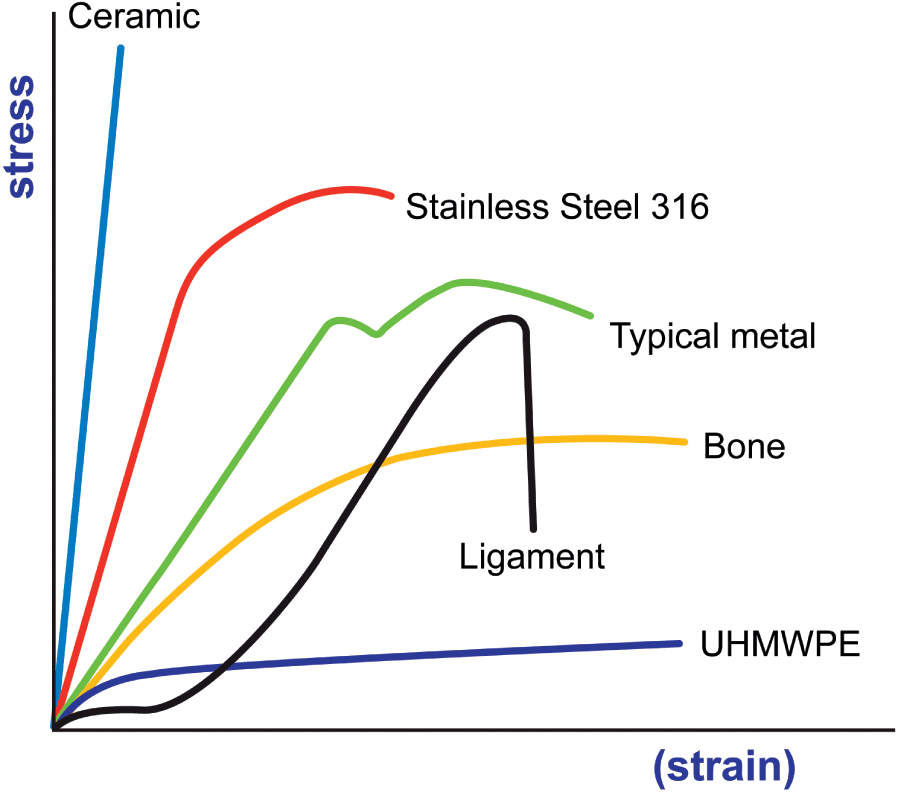

Stress vs strain graph for ceramics.

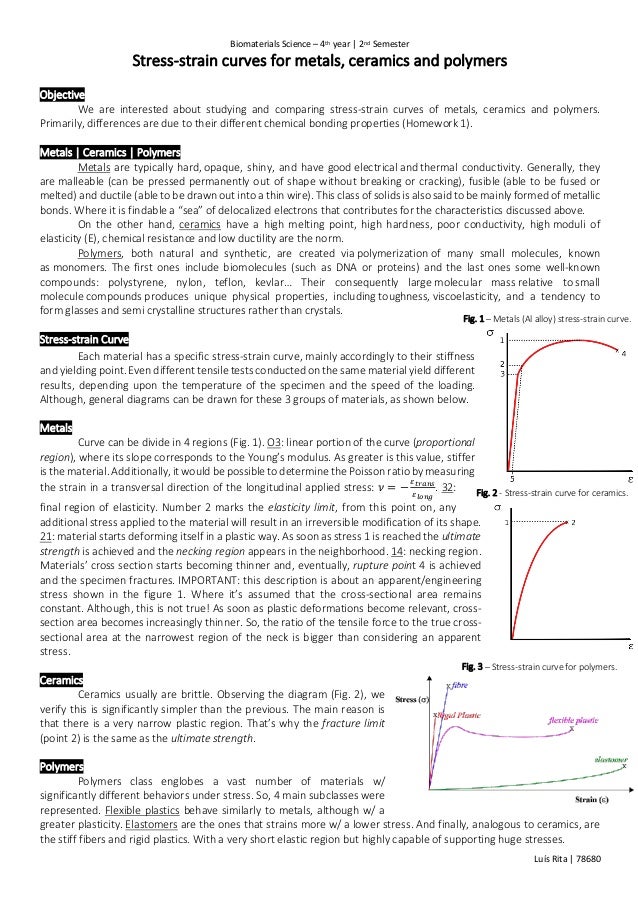

Where σ is the value of stress e is the elastic modulus of the material s ty is the tensile yield strength of the material and n is the strain hardening exponent of the material which.

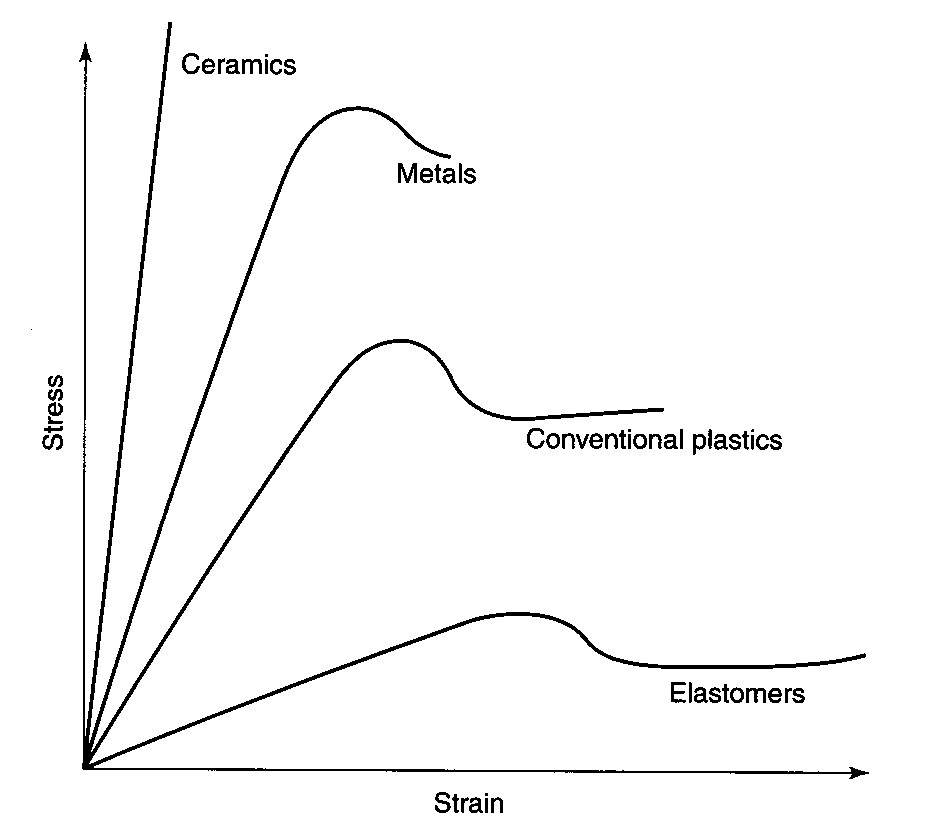

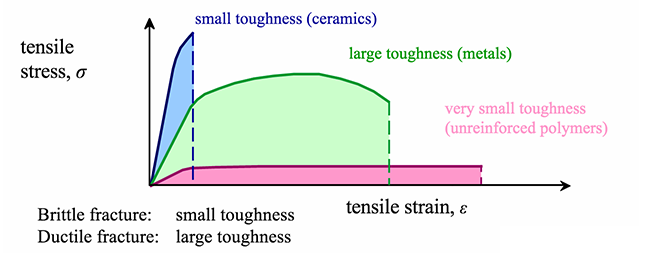

With a very short elastic region but highly capable of supporting huge stresses.

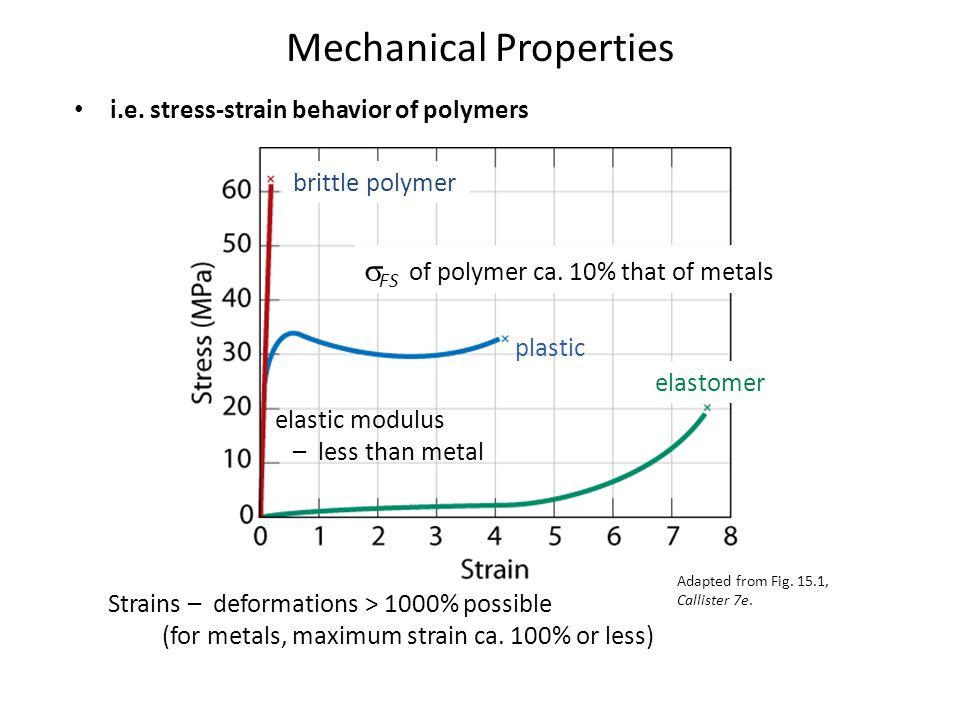

Elastomers are the ones that strains more w a lower stress.

Three point bending apparatus used determine stress strain behavior.

Lean how a wire behaves under increasing load using the stress strain graph.

7 22 callister rethwisch 5e.

The stress strain curve is approximated using the ramberg osgood equation which calculates the total strain elastic and plastic as a function of stress.

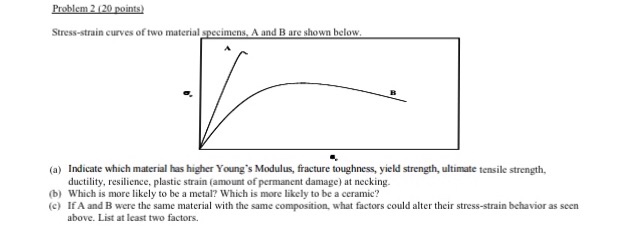

In this the stress is plotted on the y axis and its corresponding strain on the x axis.

For brittle ceramics a three point bending apparatus shown in the figure below is used determine the stress strain behavior and the measurement results are used to calculate an equivalent modulus of elasticity.

Represents straightening of the crimped ligament fibrils.

Stress vs strain curve.

Also learn about the stress strain graph for various materials like brittle ela.

Deformation mechanism maps provide a visual tool categorizing the dominant deformation mechanism as a function of homologous temperature shear modulus normalized stress and strain rate generally two of these three properties most commonly temperature and stress are the axes of the map while the third is drawn as contours on the map.

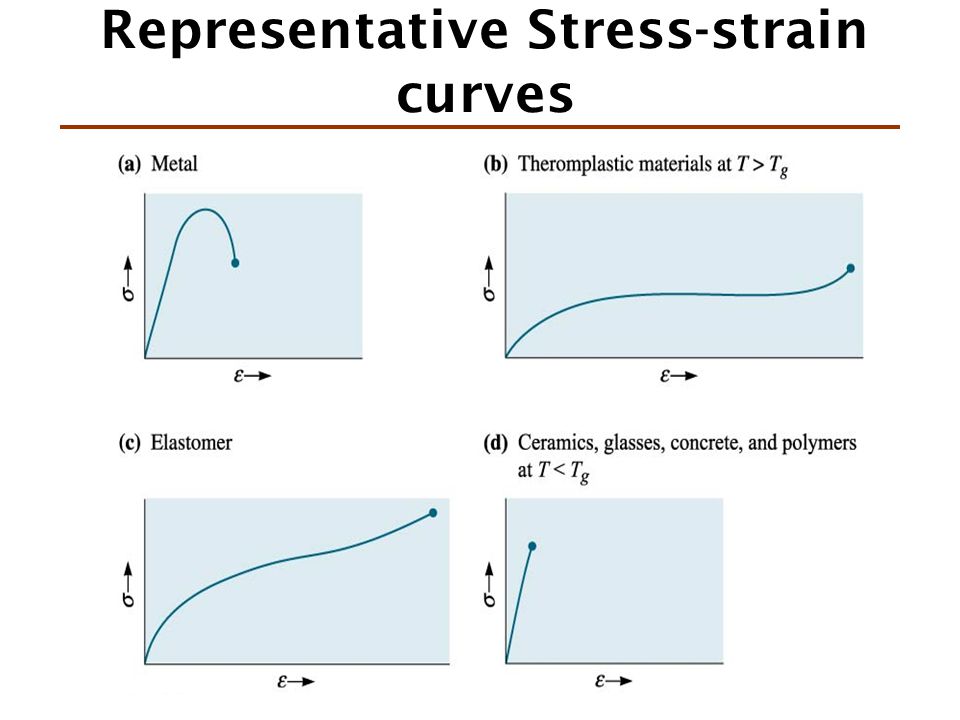

1 metals al alloy stress strain curve.

The electric strain gauge was used to study the deformation of several types of ceramic materials under stress.

2 stress strain curve for ceramics.

The zone where a material will return to its original shape for a given amount of stress toe region applies to a ligaments stress strain curve.

Mechanical properties of polymers.

7 18 callister rethwisch.

After plotting the stress and its corresponding strain on the graph we get a curve and this curve is called stress strain curve or stress strain diagram.

It was found that they behaved as elastic materials.

To populate the map constitutive equations are found.

Derived from axially loading an object and plotting the stress verses strain curve.

While some of the stress strain curves for polymers might look similar to ones for metals polymers are mechanically different than metals or ceramics.